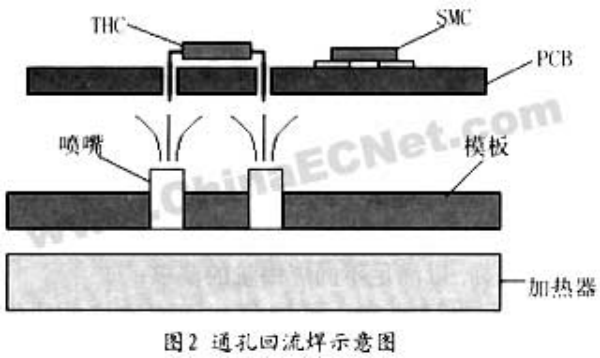

Through-hole reflow soldering, sometimes referred to as reflow soldering of classified components, is on the rise. Through-hole reflow soldering process is to use reflow soldering technology to weld the plug-in components and special-shaped components with pins. For some products such as SMT components and perforated components (plug-in components) less, this process flow can replace wave soldering, and become a PCB assembly technology in a process link. The best advantage of through-hole reflow soldering is that the through-hole plug can be used to obtain better mechanical joint strength while taking advantage of SMT.

The advantages of through-hole reflow soldering compared with wave soldering

1.The quality of through-hole reflow soldering is good, the bad ratio PPM can be less than 20.

2.The defects of solder joint and solder joint are few, and the repair rate is very low.

3.PCB layout design does not need to be considered in the same way as wave soldering.

4.simple process flow, simple equipment operation.

5.The through-hole reflow equipment occupies less space, because its printing press and reflow furnace are smaller, so only a small area.

6.The Wuxi slag problem.

7.The machine is fully enclosed, clean, and smell free in the workshop.

8.Through-hole reflow equipment management and maintenance is simple.

9.The printing process has used the printing template, each welding spot and the printing paste quantity may adjust according to the need.

10.In the reflow, the use of a special template, the welding point of the temperature can be adjusted as needed.

The disadvantages of through-hole reflow soldering compared with wave soldering:

1.The cost of through-hole reflow soldering is higher than that of wave soldering because of solder paste.

2.through-hole reflow process must be customized special template, more expensive. And each product needs its own set of printing template and reflow template.

3.The through hole reflow furnace may damage components that are not heat resistant.

In the selection of components, special attention to plastic components, such as potentiometers and other possible damage due to high temperature. With the introduction of through-hole reflow soldering, Atom has developed a number of connectors (USB series, Wafer series... etc.) for through-hole reflow soldering process.

Post time: Jun-09-2021