1. Market concentration continues to increase

By the continuous traction of the development and progress of the downstream market, the requirements of supporting electronic components continue to improve, the competitive advantage of world-class manufacturers with strong strength is becoming increasingly prominent, and the global connector market concentration is getting higher and higher.

The market share of the world's top ten connector companies increased from 41.60% in 1995 to 55.38% in 2021. Although China is the world's largest market for connectors, due to a late start, products are gradually cutting from the low-end to the high-end, and market concentration is rapidly improving. In this case, domestic high-quality connector companies, especially listed connector companies, can often be better developed and actively layout high-end connector products.

2, the pace of localization replacement accelerated

Since the 1990s, well-known connector manufacturers in Europe, the United States and Japan have successively transferred their production bases to China and invested in factories in the Pearl River Delta and Yangtze River Delta. In this context, China's private connector enterprises are gradually growing. The research and development capacity of domestic manufacturers continues to improve, and gradually expand the connector market share by virtue of advantages such as low cost, close to customers, and flexible response.

At present, the high-end connector market is still dominated by international first-class manufacturers, but the rise of downstream local enterprises has also promoted the growth of domestic manufacturers. International trade frictions lead to increased cross-border procurement uncertainty, downstream local enterprises both reduce the cost of raw materials, and suppliers have close to the demand for production, so more and more downstream local enterprises tend to purchase the same quality standards under the price of more favorable domestic connectors, thereby accelerating the promotion of connector localization and localization of production.

In the face of the new international development situation, the Chinese government proposes to build a new development pattern based on domestic recycling and mutual promotion of domestic and international recycling, focusing on improving the stability and competitiveness of industrial and supply chains. Therefore, the localization of substitution is expected to become an important issue in the recent industrial development, so domestic manufacturers can grasp the current development window, comply with the trend of localization of substitution, so as to expand market share, and further narrow the gap with the international first-class manufacturers.

3, standardization to customization evolution

Traditional connectors are passive devices, more as standardized products, in recent years, with the personalized design of downstream products and functional richness, structural complexity, so as to the upstream connectors and other basic components of the customization of the demand gradually increased.

On the one hand, as downstream products become more and more intelligent, customers have more diverse requirements for connector shape, size and function; On the other hand, due to the increasing concentration of the downstream industry, leading enterprises in various segments have become major customers of connector manufacturers' key services, and such customers often put forward higher customized needs for connectors in order to build differentiated characteristics of products and improve the overall identification of products.

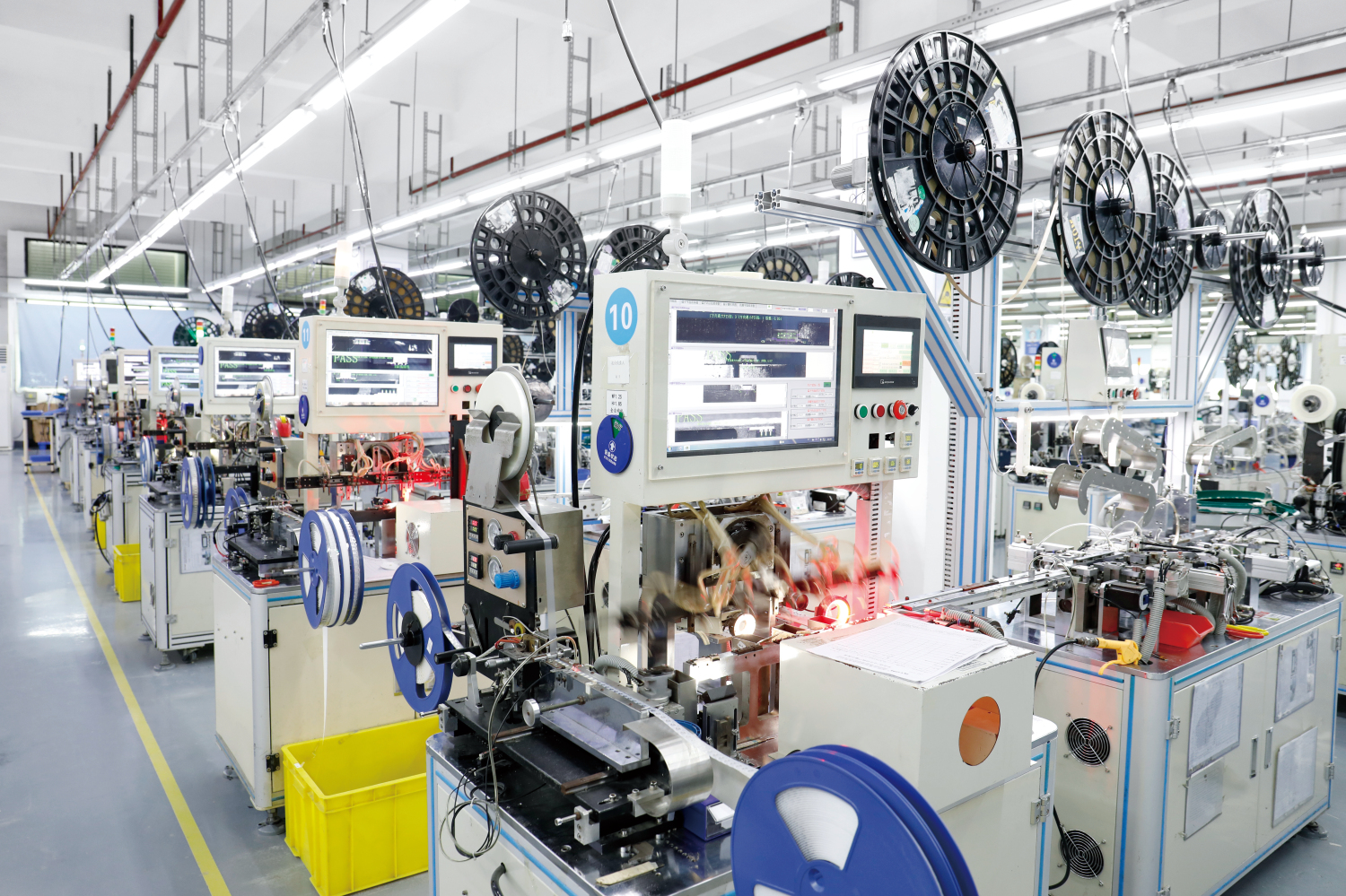

In summary, connector manufacturers need to pay more and more attention to the improvement of customization capabilities, including reducing the cost of customization and shortening the customization time, so that a large number of customized products can be quickly promoted to the market. In this context, connector manufacturers are required to have customized service advantages in the whole process of product development, process production, and quickly achieve customer needs for comprehensive connection technology solutions and multi-variety, small-batch rapid delivery needs through modular design and flexible manufacturing.

Post time: Jun-28-2024